Production of the -Aska Team Build- series’ -HD-Yozakura '20 Summer A, S/ATB- “Summer Sakura”, has started!

We asked Yoshida Yukihiro, a design engineer of the Aska Workshop for a comment on the inlay work for this series.

Q&A With Yoshida

--When did you decide what this time’s Summer Sakura design was going to be?

Yoshida: If we think about summer cherry blossoms this year, we would be doing so around March, The “Summer Sakura” or Summer Cherry Blossoms line started in 2018, making this its third installment. For the 2018 design, we based it on the concept of the firework and the cherry blossoms forming the summer scenery of the town, for 2019, the inspirations was “The Swallowtail butterflies and the cherry blossoms”. The schedule was getting a little tighter every year, and I didn’t really have much time to think about them, but this year I was able to start relatively ahead of time, so that gave the necessary time to get everything going nicely.

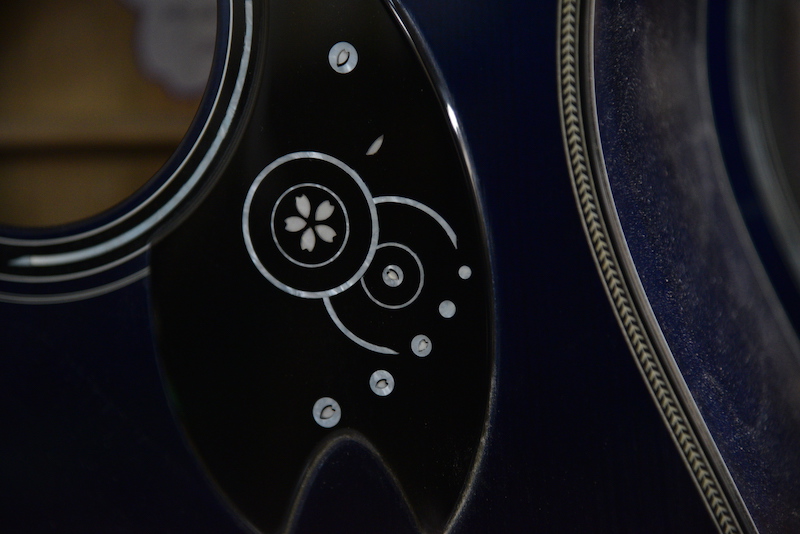

This year's summer cherry blossoms models were inspired by the rainy season, which is right about when you start getting that feeling that "the summer is coming", and fittingly, the theme is "rain and cherry blossoms". The design of blossom petals gently falling and creating ripples on the surface of the water are laid throughout the guitar.

--What kind of processes do you go through when designing for a guitar?

Yoshida: First of all, I will collect as much information and references as possible, and then I start thinking about what would make for an interesting design in my head. Then, I write those designs down as a rough sketch on a notepad and organize my mind around that to get to the actual pattern.

When creating a guitar, you have to carefully design everything before you can start working on the guitar to make sure that everything from the decoration and body you have is ready from the get-go.

Once the rosetta’s design is complete, the head top is decided, then the fingerboard, the bridge (if decorating), and finally the pickguard.

--For fingerboard inlays, is having to maintain the position parkers and their set sizes a constraint?

Yoshida: The position markers are such an essential thing to guitars that I got used to dealing with them a long time ago, although ut was hard to get used to them in the beginning

--What kind of work do you do other than design work?

Yoshida: My department is basically my own, and I not only work on designs but also operating the CNC router data production, as well as to operate engraving machines and laser machines. For example, when it comes to electric guitars when a project to create a new HSS layout model is launched if there is only processing data for a 3 single pickups layout, I create new data, and if the size of the pickup used for the same HSS is different, I also create dedicated processing data for that too.

Aska's guitar production involves many custom-ordered products and custom-ordered model projects, so it really helps to have the tools and skills to be very detailed and tight in the delivery.

The ‘operating’ work is about 60%, and I think that the rough design is sewn in between, and the remaining 40% is the work that actually involves shaping out the designs. And from many different machines, a new scheme is born. I spend a couple of minutes between these kinds of processes, devising ideas, and devoting myself to design.

--What design have you been working on lately?

Yoshida: I’m just finishing up the model that will be coming next fall. Since 7 pieces will be bundled under one theme, I have to worry about where to have a commonality and where to add accents and uniqueness.

Final touches are being given to this model, and it should be ready during June.